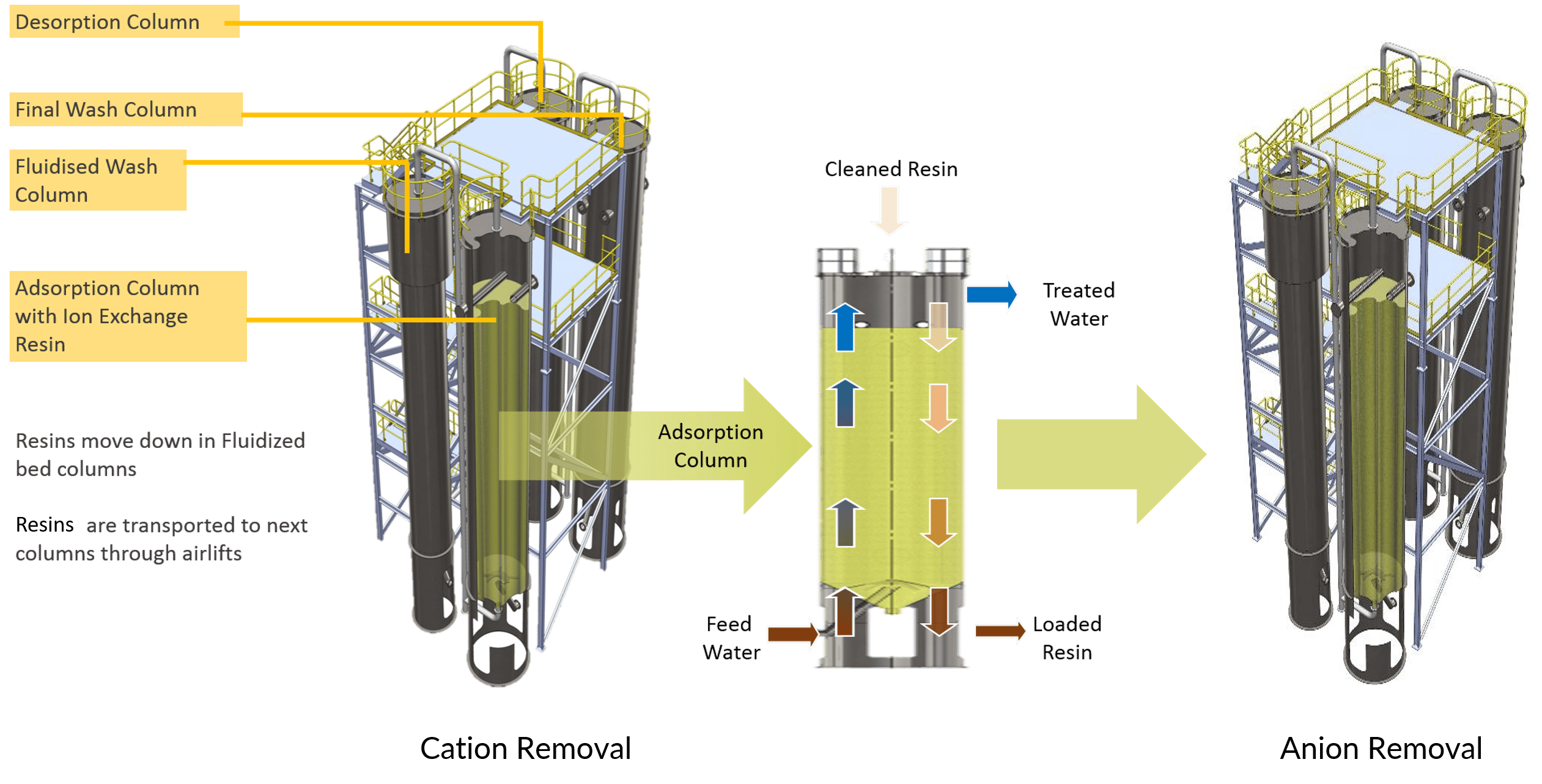

Our Continuous Ionic Filtration (CIF® )technology uses continuous ion exchange and physical filtration (if required) to selectively remove contaminants from water. The technology is proven and built on the foundations of ion exchange, a process that has been used in the water industry for over 50 years.

CIF® uses a moving bed of charged resin beads to attract and remove ionic species from water whilst filtering the water of suspended solids, ensuring optimum efficiency and continuous high performance. Commercially available ion exchange resin can be used in the system, with the resin type chosen based on the contaminants being targeted.