EVAPX®

Low Energy Evaporation and Crystallisation

EVAPX® is a low energy evaporation and crystallisation technology which uses a dry air stream to efficiently evaporate wastewater and brines.

EVAPX® evaporates wastewater using humidification and dehumidification, allowing evaporation to occur at temperatures lower than boiling point and at atmospheric pressure, reducing the heating required and cost associated with pressure vessels.

The distillate produced by EVAPX® is highly pure water, which can be reused or safely discharged to the environment. EVAPX® can be configured to produce a concentrated liquid brine, a slurry, or solid waste depending on the client’s needs. EVAPX® can be powered by electricity, steam, waste heat or solar energy.

Process Description

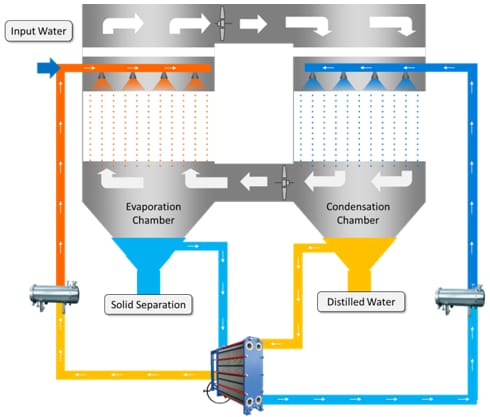

Water enters the evaporation chamber where is evaporated using a dry air stream. The solids settle at the bottom of the evaporation chamber and are separated out. The humidified air moves to the condensation chamber where it condenses as distilled water, and the heat is recovered. Heat is applied to the heat exchanger instead of directly to the evaporation chamber, making the system highly resistant to scaling and fouling.

Applications

EVAPX® can be applied to a range of applications where brines or difficult to treat waste streams are produced. Typical applications include:

- Industrial Water – zero liquid discharge solutions for difficult waste streams and brines

- Power Plants – evaporation of difficult to treat waste water and brines, often using the plant’s waste heat for reduced capital and operating cost

- Mining Water – producing a pure distillate and solid waste from tailings, process water, brines, or acid mine drainage.

- Agriculture – evaporating difficult to treat wastewater and avoiding brine ponds

- Reverse Osmosis Brines – concentrating brines or creating a slurry or solid waste, avoiding the need for evaporation ponds

- Evaporation Pond Remediation – treatment of high TDS water in evaporation pans, producing a solid waste and a high quality distillate for reuse or discharge

Benefits

LOW ENERGY CONSUMPTION AND CAPABLE OF UTILISING WASTE HEAT TO REDUCE COSTS

VERY HIGH WATER RECOVERY

(TYPICALLY >99%) AND LOW WASTE PRODUCTION SINCE THE BRINE RESUSE

HIGHLY RESISTANT TO SCALING AND FOULING SINCE EVAPORATION OCCURS AWAY FROM HEAT INPUT

LOW CAPITAL AND OPERATING COSTS

EASY OPERATION, CLEANING, AND MAINTENANCE

Get in touch

Find out how we can help with your water treatment challenge using the EVAPX® technology.