BIOCLENS®

Lens Encapsulated Bacteria

Our BIOCLENS® technology uses encapsulated bacteria in a lens shaped carrier to provide intensified ammonia and nitrate removal to very low levels.

Our BIOCLENS® technology uses bacteria encapsulated in lenses as a biocatalyst to enhance and accelerate natural biological processes which break down organic matter.

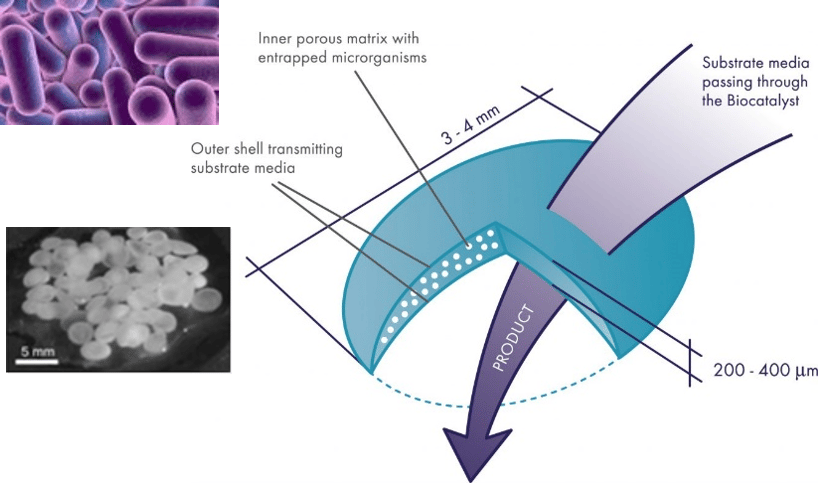

The lenses contain living bacteria which is immobilised in a stable, porous PVA gel matrix. As these are stirred in a reactor, water and dissolved impurities diffuse through the lenses and come in contact with the bacteria, causing targeted reactions to occur. The specific bacteria required for nitrification or denitrification can be encapsulated in the lens, creating intensified activity. The encapsulation protects bacteria in saline environments and from high concentration of ammonia or nitrate in the feed (above 1,000ppm).

BIOCLENS® Diagram

Targeted Reactions

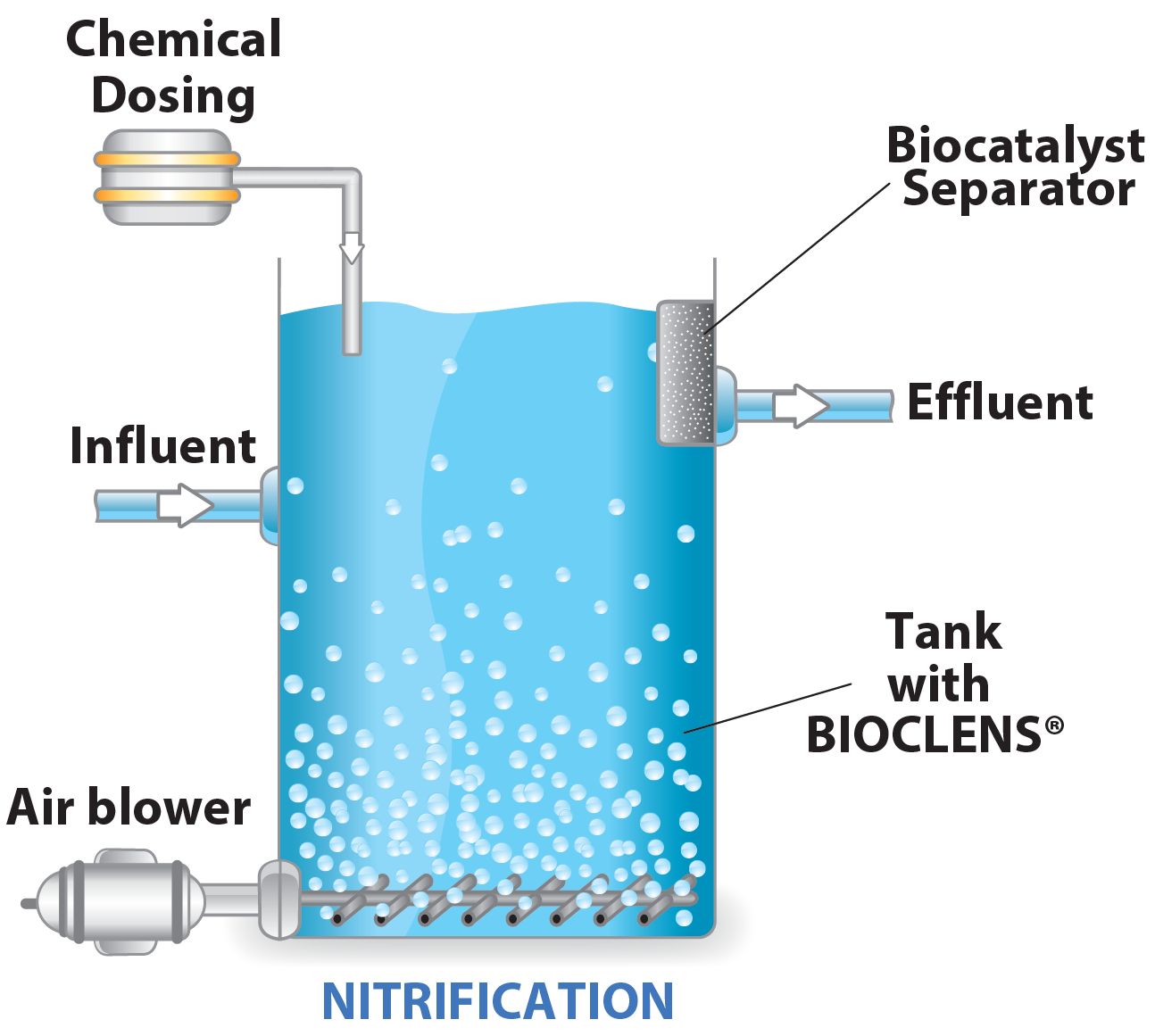

Ammonia Removal

Ammonium (NH4+) in the wastewater permeates into the lens to allow the ammonia oxidizing bacteria (AOB), embedded inside lens, convert the ammonium (NH4+) to nitrite (NO2–).

NH4+ + 1.5 O2 → NO2–+ 2H+ + H2O

Then the nitrite oxidizing bacteria (NOB), also embedded in the lens, then convert nitrite (NO2–) to nitrate (NO3–).

NO2–+ 0.5 O2 → NO3

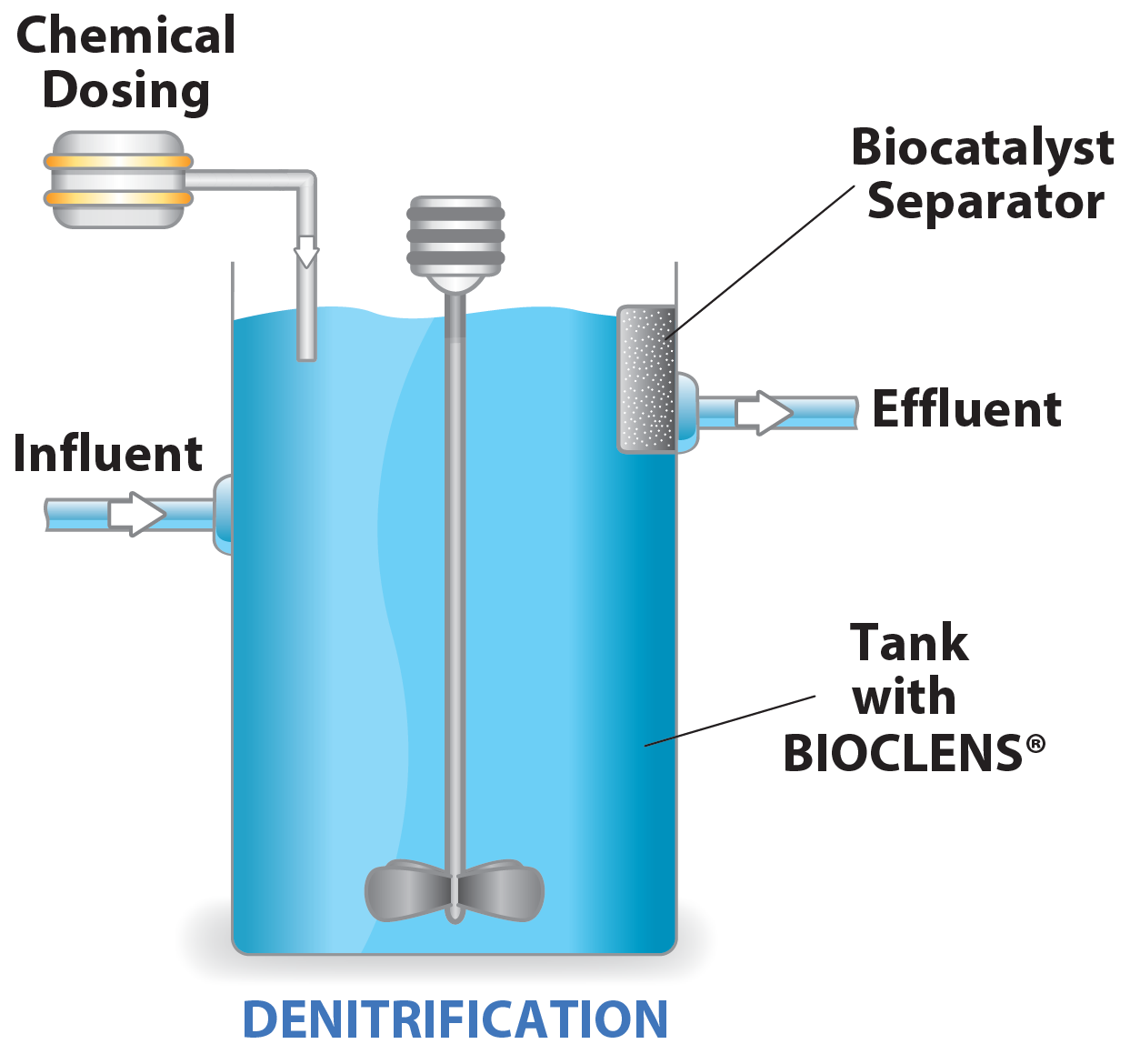

Nitrate Removal

Nitrate (NO3–) in the water permeates into the lens

Nitrate reducing bacteria embedded inside the lens convert the nitrate (NO3–) to nitrite (NO2–)

Nitrite (NO2–) is then converted to nitrogen gas (N2)

Both reactions require a carbon source as an electron donor

2NO3–+ 10e– +12H+ → N2 + 6H2O

Benefits

ACHIEVE VERY LOW AMMONIA AND NITRATE LEVELS (<1PPM)

SMALLER SITE FOOTPRINTS DUE TO HIGH BACTERIA ACTIVITY

HIGH ACTIVITY IN SALINE ENVIRONMENTS AND WITH HIGH INFLUENT CONCENTRATIONS DUE TO ENCAPSULATION

LOW CAPITAL AND LIFE-CYCLE COSTS

Applications

BIOCLENS® can be applied to a range of industries:

- Municipal Reuse – Ammonia and nitrate polishing to allow reuse or safe discharge from water treatment plants

- Surface Water Treatment & Groundwater Treatment – removal of ammonia and nitrates for potable use or for industrial applications

- Aquaculture & Agriculture – nutrient removal to allow reuse or safe discharge of water

- Mining Water – removal of nutrients for water reuse or discharge

- Industrial Water – elimination of nutrients in contaminated water for reuse or discharge

Get in touch

Find out how we can help with your water treatment challenge using the BIOCLENS® technology.