Clean TeQ Establishes the Future Element Joint Venture to Accelerate Expansion into Global Mine Tailings Management

14 November 2023

Highlights:

- Clean TeQ forms a 50/50 Joint Venture, the Future Element Joint Venture, with mine tailings management company Future Element Pty Ltd (“FE”), to focus on tailings management, metal recovery and waste remediation opportunities.

- Clean TeQ will provide the JV with licenses for its proprietary ATA® accelerated dewatering technology and its suite of CLEAN-IX® ion exchange technologies.

- The JV has immediate access to both Clean TeQ’s and FE’s opportunity pipeline

Clean TeQ Water is pleased to announce it has established a 50/50 Joint Venture, Future Element Operations Pty Ltd (“Future Element JV”) with mine tailings management company Future Element Pty Ltd.

”This is an exciting time for Clean TeQ as we look to leverage our technologies into market segments that are long term value accretive for our shareholders. The JV with Future Element combines years of technical innovation and development with highly credentialled and commercially orientated executives to deliver solutions to the mining industry for its most critical problems. We aim to transform the industry and lead with environmentally sound tailings rehabilitation while generating material cashflows from what were previously considered waste management liabilities."

Peter VoigtCEO, Clean TeQ Water

Mine Tailings Opportunity Overview

Mine tailings are the waste solids that remain after separating the targeted minerals of a mining operation from the remaining uneconomic minerals. The global inventory of mine tailings is estimated at 282 billion tonnes, with 16 billion tonnes of new mine tailings being produced every year, representing a significant opportunity to use Clean TeQ technologies to convert liabilities into valuable assets. The mining industry’s social licence to operate depends on environmentally sound tailings rehabilitation. Our strategy is to raise environmental standards and reduce tailings management costs via sustainable metal production and enhanced water management.

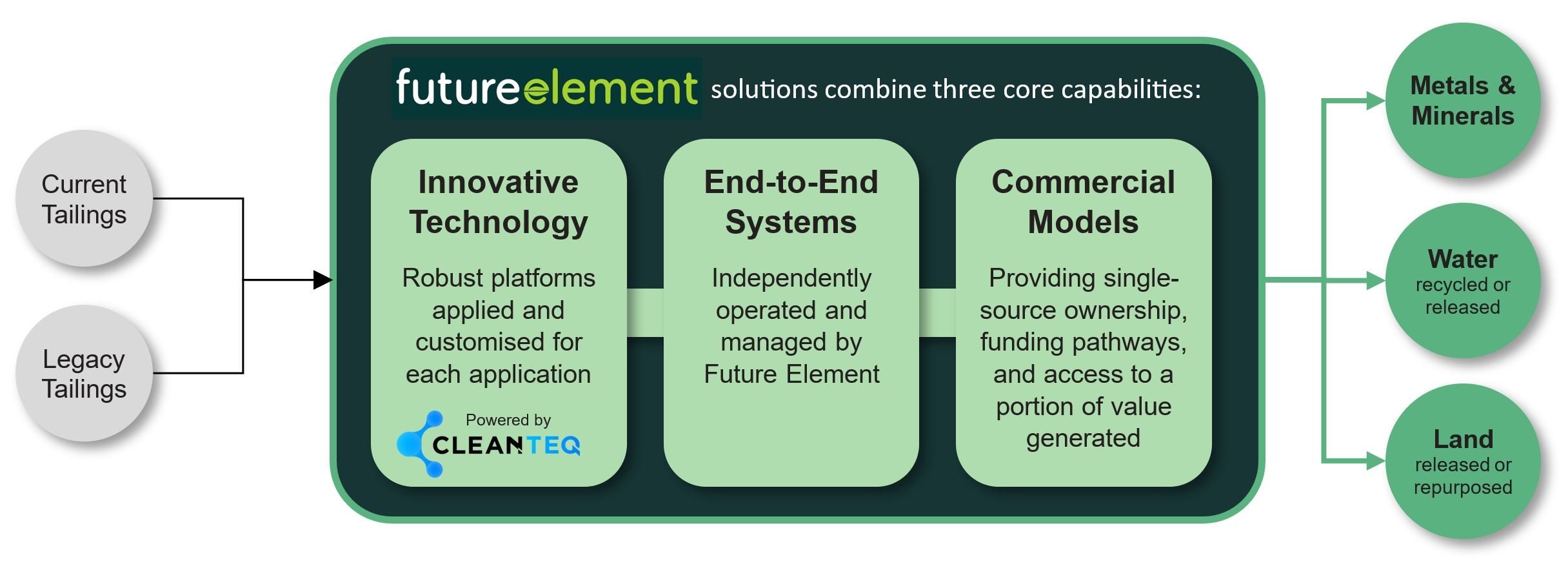

With the licensing of Clean TeQ’s proprietary ATA® and CLEAN-IX® technologies to the Future Element JV, we have established a business that can offer the mining industry a holistic, end-to-end mine tailings rehabilitation solution that:

- transforms tailings into benign and/or valuable products via separation of solids and water to allow solid materials to be rehabilitated or repurposed and water to be recycled or released;

- unlocks tailings value, via recovery and monetisation of metals and minerals, providing new profit streams and the ability to offset rehabilitation costs and liabilities; and

- encompasses development, funding and operation using best-in-class tailings management by an experienced team with a track record in asset delivery.

About Future Element Pty Ltd

FE was founded by John Carr and Patrick Walta, who also founded New Century Resources Limited and were responsible for the acquisition and re-development of the Century Zine Mine in Queensland into Australia’s largest ever tailings reprocessing operations. Since restarting operations at the existing Central Mine, New Century Resources has delivered over 1,000,000 tonnes of zinc concentrate into the global market, while also delivering material reductions to the rehabilitation footprint of the mine site.

Additional team members are co-founders Brent Slattery and Dennis Gibson. Brent held prior roles at BCG and BHP. Dennis, a former Rio Tinto executive and CTO Mining at Black & Veatch, is an industry veteran with extensive global water and tailings management expertise.

FE provides holistic solutions to rehabilitate tailings and water and is targeting sites with the potential for production of valuable products from current and historic tailings at both operating and legacy mine sites. FE’s bespoke and end-to-end solutions will use Clean TeQ technology for the recovery of metals and minerals, treatment of water to be discharged or recycled and rehabilitated land ready for release back to communities.

The Future Element commercial model, combining delivery of best-in-class tailings and water rehabilitation with metal recovery from tailings.

Building on that track record, Future Element is focused on delivering superior outcomes for current and legacy mines globally. Tailings represent both an enormous environmental and social challenge for mining but also a significant opportunity to provide sustainable metals and minerals from existing operations whilst reducing impact and improving safety.

Further information on Future Element can be found at www.futureelement.com.

Joint Venture Agreement

Clean TeQ and FE have executed a Shareholders Agreement and formed a 50/50 Joint Venture, Future Element Operations Pty Ltd for financing, acquiring and/or joint venturing a portfolio of mining assets to provide retreatment and rehabilitation, as well as produce critical metals required for global energy transition from tailings facilities, based on proprietary Clean TeQ and Future Element technologies and capability.

Under the terms of the agreement Clean TeQ will provide technology licenses for the use of its ATA® rapid dewatering technology and the full suite of CLEAN-IX® technologies. Clean TeQ will also provide partial seed funding for up to 18 months, estimated at $250k per quarter. FE will contribute the team at a fixed subsidised compensation, as well as an established pipeline of large-scale projects and partnerships.

The Board of Directors of Future Element JV will consist of two directors from Clean TeQ and two directors from FE.

Next Steps

The Future Element JV management team has been assembled and is advancing several opportunities within the global mine tailings management industry, with a view to progressing commercial agreements on key foundation projects. The JV is currently planning pilot-scale testing at several sites in the coming months leading to full scale commercial implementation once proven.