Clean TeQ awarded contract to supply DESALX® technology for mine water treatment plant

13 December 2017

”Clean TeQ, through its wholly-owned subsidiary Clean TeQ Water Pty Ltd, has entered into a landmark agreement with Fosterville Gold Mine Pty Ltd (Fosterville) to design, supply and commission a two million litre-per-day Clean TeQ DeSALx® mine water treatment plant.

Sam RiggallClean TeQ Managing Director

Mr Robert Friedland and Mr Jiang Zhaobai, Co-Chairmen of Clean TeQ Holdings Limited (Clean TeQ or Company) (CLQ:ASX; CTEQF:OTCQX), and Mr Sam Riggall, Chief Executive Officer made the announcement today.

The award of the contract follows a period of extensive due diligence and test work conducted by Fosterville to validate the efficacy of Clean TeQ’s DeSALx® system for the treatment of mining process waters. The contract serves as a significant milestone for the Clean TeQ Water division. Sustainable water management is becoming critically important in the mining industry as environmental regulations are tightened globally and water scarcity increases. The Fosterville water treatment plant is an important reference project for Clean TeQ’s DeSALx® technology, which is expected to add significant momentum to the growing pipeline of Clean TeQ Water projects.

Project Location

Fosterville operates the Fosterville Gold Mine near Bendigo, around three hours drive north-west of Melbourne. During the mining process, groundwater is produced which is currently stored at the surface in limited capacity dams on the mine site. To create a more sustainable water management strategy, Fosterville approached Clean TeQ to provide a system that will treat the mine water to match the quality of the region’s underlying aquifer. Fosterville can then use managed aquifer injection (MAI) to return the water to its natural source, or alternatively, use the treated water from the Clean TeQ plant for further treatment and subsequent recycling and re-use of the water.

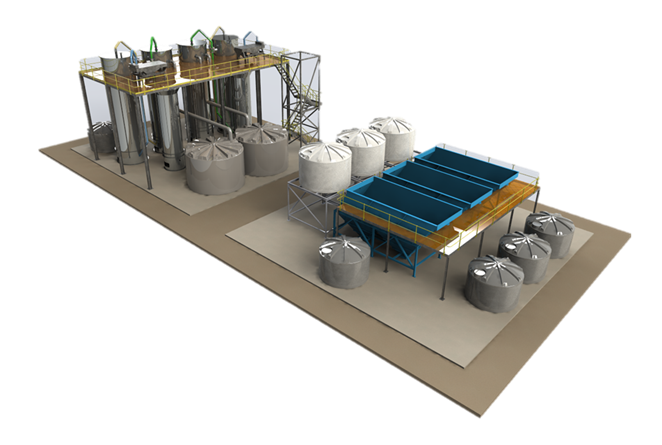

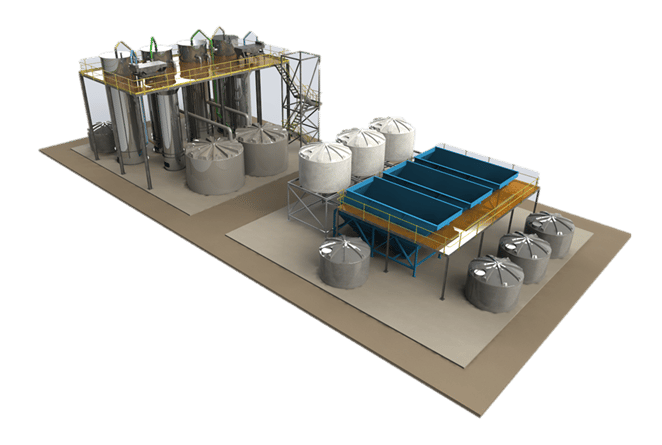

The DESALX® Technology

The Fosterville water treatment plant comprises an integrated precipitation and continuous ionic filtration process (DeSALx®). The precipitation process removes arsenic and antimony from the water as a coprecipitate. The water is then treated by the DeSALx® process to remove hardness, sulphate, and other dissolved metals. DeSALx® technology is ideal for complex mine wastewater treatment. The DeSALx® process can be used as a standalone or as a pretreatment for membrane-based water treatment systems.

As the DeSALx® by-product is gypsum-based, it is compatible with Fosterville’s currently established lime treatment facility and provides a zero-brine water treatment solution. Design of the Fosterville water treatment plant is already underway, with equipment supply, installation and commissioning all scheduled for 2018. Clean TeQ Water is actively engaged with several mining companies globally in testing our unique continuous ion exchange systems for the treatment of process water treatment for recycling or environmental discharge.