Metal Recovery Plants

Design, Supply, and Installation of Metal Recovery Systems

Clean TeQ Water is a world leader in metal recovery solutions. Our unique technology can economically recover dissolved metals from a range of dilute sources.

The mining and mineral processing industries use a range of processes for metal recovery from leached solutions and slurries. Ion exchange is a common hydrometallurgical processes which is well suited for recovery of low to moderate concentration targets of dissolved metals from complex solutions.

Traditional ion exchange often experiences low ion exchange efficiency, high reagent consumption, and requires large downstream purification and concentration circuits. These systems can also experience issues during upstream process upsets, including increases in suspended solids concentrations.

Clean TeQ Water’s CLEAN-IX® technology aims to overcome these issues while providing customers a range of additional benefits.

Metal Recovery Using CLEAN-IX®

Clean TeQ Water’s CLEAN-IX® technology provides highly efficient extraction and purification of a range of metals from slurries and solutions. It typically achieves an extraction rate of typically more than 98% of the contained metal in the solution, and can economically recover the metal contained in dilute streams, such as process waters or tailings dams.

Our continuous, counter-current approach fully utilises the capacity of the ion exchange resin, and produces high concentration, high purity eluates. This allows for smaller downstream processing circuits and the ability to go direct to precipitation, crystallisation, or electrowinning.

We provide turn-key metal recovery solutions for customers that can integrate seamlessly into existing processing circuits or infrastructure on site.

Recoverable Metals

We can recover a range of metals using CLEAN-IX®, including those highlighted in the periodic table below.

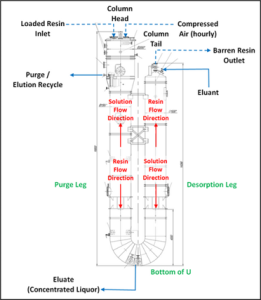

CLEAN-IX® Example: U-shaped Moving Bed Desorption Column

The key benefit of our U-shaped column provides over other styles of desorption columns is its ability to produce eluates with exceptionally high concentrations. This concentration effect is typically accompanied by partial purification and near-stochiometric reagent consumption. The concentration effect occurs due to the presence of various “zones” in the U-column, as presented in the figure below:

As the resin moves through the column, the dilute desorbing reagent in the loading/scrubbing zone exchanges for low-affinity impurities leaving the resin enriched in the targeted metal and depleted in impurities. The resin then proceeds to the desorption zone where contact with the concentrated eluant occurs, and desorption takes place. The counter-current flow of resin and eluant results in a very high concentration of metal ions in a small volume product stream.

Advantages of CLEAN-IX®

OPTIMAL METAL LOADING AND FULL USE OF THE RESIN’S LOADING CAPACITY

CONCENTRATED ELUATES, HIGHER PURITY METALS STREAMS AND SMALLER DOWNSTREAM PROCESSING CIRCUITS

CLOSE TO STOICHIOMETRIC REAGENT USE AND LESS WASTE

ALLOWS FOR DIRECT PRECIPITION, CRYSTALLISATION, OR EW – PROVIDING SIMPLIFIED FLOWSHEETS

How Can Clean TeQ Help?

We provide a full range of metal recovery services through the experienced hydrometallurgists in our metal recovery division. We have expertise in all areas required to bring a metal recovery project to life, including:

- flowsheet development

- test work

- piloting

- feasibility studies

- demonstration plants

- design and installation of full scale systems

Contact us to discuss your project and how our technologies and services can help your project.

Get in touch

Find out how we can help with your metal recovery challenge using the contact form below.